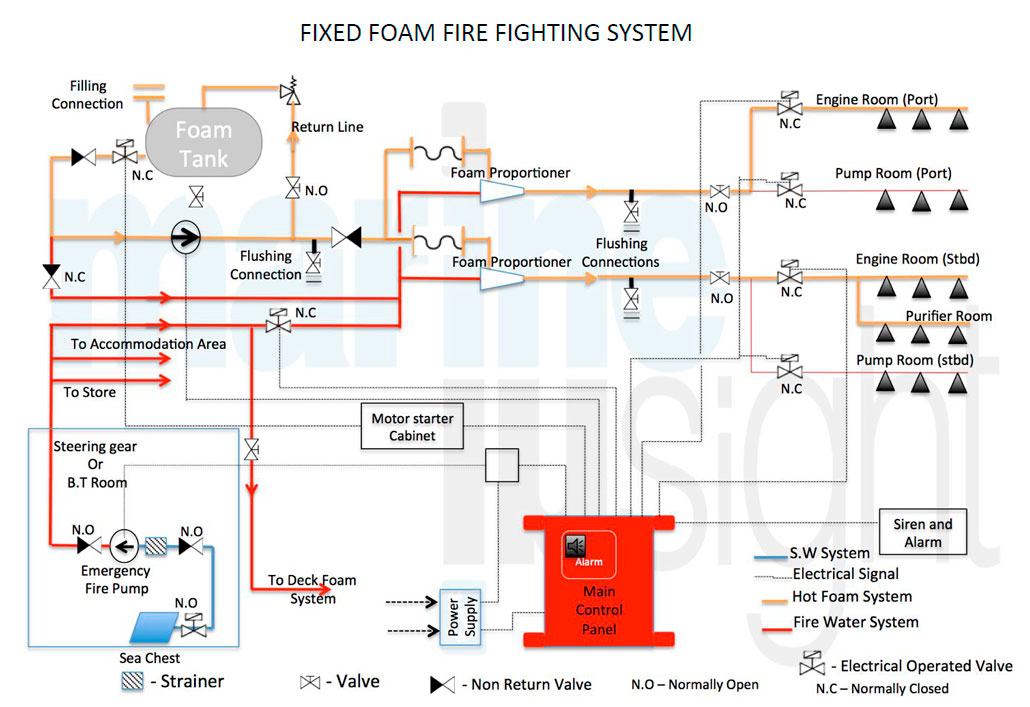

A high expansion fixed foam fire fighting system is used in the engine room to provide protection to some of these following engine room areas/equipment:

Main switch board Incinerator room Purifier room Engine casing Pump room Electrical workshopFoam outlets are installed at various locations in the engine room for foam discharging. Generally, 4-5 main supply lines are fitted with foam generators at strategic locations. They produce and supply the foam to the discharge points.

These generators are designed as an integral part of the hot foam system, which takes air from the protected space even if the space is filled with combustion gases or smoke. Constructed from stainless steel, they are provided with nozzles to send foam/ water mixture in to the housing at higher speed.

This speed creates a negative pressure, which sucks the surrounding air/ gases from the space to create high expansion foam mixture.

The foam is produced by mixing the chemical with the seawater, which is supplied by either fire and GS pump or emergency fire pump. The mixing ratio of foam making chemical to seawater is normally 2: 98.

The foam making chemical is kept in the foam room in a steel tank, which supplies the chemical to the mixers or proportioned placed at different locations. The foam is supplied to these mixers/ proportioned via a foam pump. They are also supplied with seawater to produce the required foam that is to be discharged for fire fighting.

Generally, there are two foam mixers i.e. one for the starboard side and one for the port side. One foam mixer/ proportioner will be supplying foam to the pump room line.

Preparation for Operating Foam System:

Check the foam tank is filled with sufficient foam chemicals Check for any sign of leakage or damage to the foam tank Check all main fire sea valves for foam system are in open position During cold weather, the pump and system heater should be ON Switch on the main power and select the ОР/ Operational/ Discharge or similar mode in the control panel Ensure system flushing valve is in closed condition Open the hot foam system release cabinet door Press the alarm button for flooding of engine or pump room Ensure all personnel from the affected space have been evacuated Shut and seal the compartment by closing all the doors and ventilations Press the button for injecting the foam into the designated compartment The foam will be injected after 120 sec of the command and during this period only water in injected The foam system has to switched off manually once the fire in the affected spaces has been suppressed For re-entry in the space, ensure it is cooled down and the enclosed space entry precautions are takenProcedure for Cleaning the Foam System:

Once the operation of foam system is finished, shut down the foam pump and sea water supply pump Close the isolating valve which connects the foam line to the foam tank so that water does not enter the foam tank Open the flushing valve Ensure foam tank discharge valve is closed Start the sea water supply pump (emergency fire pump or GS pump) and foam pump Attach hose to test connection hydrant of the foam system with its discharge to overboard Open the test connection hydrant valve and flush the system Stop the foam pump and keep running the water pump This will flush the foam in the foam lines Stop the sea water supply pump and drain the line Revert all the valves to standby position

References

A Pocket Guide To Fixed Fire Fighting Systems and Emergency Procedures For Ship’s Engine Room (Author: Marine Insight)