One of the major functions of the cylinder head is to seal the combustion chamber and to accommodate other auxiliary parts such as fuel injector, air start valve, exhaust valve etc., to assist in the combustion process.

The cylinder cover of marine engine is subjected to high combustion temperature.

To tackle this condition, the cylinder head is provided with cooling water bore wherein pre-heated water is circulated to avoid thermal stresses.

The gas load produced during power stroke is transferred by means of cylinder head studs to the engine structure and then to ship’s hull via tie rods and foundation bolts.

MAN and SULZER engines have single piece, solid steel cylinder heads with bore cooling concept and centrally fitted exhaust valves. Other fitting holes are also provided in the cover (Fuel valve, start air valve, relief valve etc.).

Some SULZER engine (RTA series) models also have two piece cylinder cover - Inner and outer pieces. This design was introduced to tackle cracks in the cover body, especially in the uncooled space due to thermal expansion.

Inner piece is also known as cylinder skirt, which is made up of cast iron and outer cylinder is made of cast steel; both are tied together to form a single piece. Now the latest Rtflex series engine uses advanced design single piece cylinder cover.

Some MAN engine cylinder covers have special head studs with elastic property. These stud expands in case of overpressure of the cylinder and releases the excess pressure from the area between the liner and the head, which opens up when the head lifts. No relief valve is fitted in such type of cylinder cover.

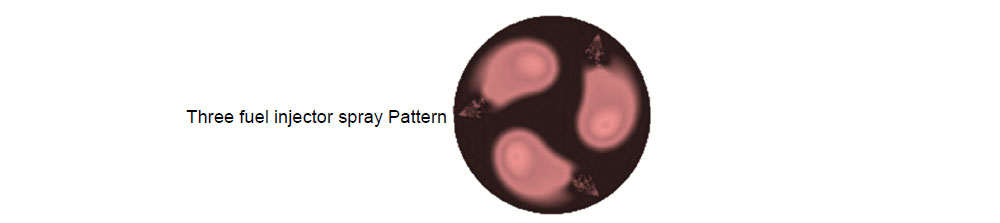

SULZER and MAN engine covers with high KW ratings use three fuel valves mounted on the top of the cylinder cover forming a triangle.

This is done to achieve efficient combustion, to reduce overheating of cylinder head and to improve cooling. If the KW rating of engine is reduced i.e. small engine, one or two fuel valves are installed.

Forged or cast steel is used for the cinstruction of cylinder cover to withstand gas load and high temperature.

Anti-corrosion cladding is applied to the cylinder covers, downstream of the injection nozzles to protect the covers from hot corrosive or erosive attack.

Problems in Cylinder HeadCommon problems in the cylinder head:

Cracks: This is the most common defect that occurs in a cylinder head, especially near the fuel valve area and exhaust seating.

Burn: Burning of cylinder head surface occurs due to flame impingement of fuel valve.

Leakage: Exhaust leakage from head occurs due to worn head gasket or improper tightening.

Distortion: Occurs due to improper tightening, overheating, casting strain

Corrosion: Acidic corrosion or due to poor water treatment

Carbon Deposit: Occurs due to improper combustion and poor fuel treatment

Inspection of Cylinder HeadInspect the following when checking the cylinder head:

Check cooling water space for deposits Check starting air valve pocket and seat for scoring or cracks Check fuel valve pocket and seat Check the combustion side of the head for deposits, overheating, and cracks Check exhaust passage for scoring and burnout Pressure test the cylinder head water side Check the condition of cylinder head gasket Check condition of relief valve and ensure it is not leaking Check all the studs are properly tightened to engine frame