New EU Ship Recycling Regulations for Inventory of Hazardous Material (IHM)

Mr. Michael Suhr, Regional Director North Europe from the classification society Ko-rean Register took part in the Senior Office Seminar in Leer on the 7th March.

Mr. Suhr spoke about the new legal requirement for an “In-ventory of Hazardous Material (IHM)” for the recycling of ships, and now applies to all ships regardless of whether they are new or old. As a result, this is a regulatory require-ment that Briese Shipping must comply with.

Therefore he was asked to prepare also a small article about this topic for the Briese News, where he kindly agreed to.

About Korean Register

Korean Register is an IACS classification society es-tablished in 1960 with the purpose of promoting safety of life, property and the protection of the marine environment. KR currently classes an inter-national fleet of more than 3000 vessels totaling 68 million GT. KR Headquarters are located in Busan, South Korea and operates a network of almost 70 offices around the world. KR is a not for profit clas-sification society which provides reliable certifica-tion and maintenance services to the world mari-time industry.

Korean Register is an established partner of Briese Shipping. KR verifies and certifies for almost the en-tire fleet of Briese Shipping the EU-MRV and IMO DCS Requirements regarding CO2 emissions.

Also is the M/V BBC Manitoba as first Briese Vessel now classed by Korean Register.

For more information about Korean Register,

visit www.krs.co.kr

From the end of 2020, all EU-registered and all EU-visiting ships above 500 GT will need to have an Inventory of Haz-ardous Materials (IHM) onboard the vessel. Approximately 35,000 ships are affected by this regulatory change and the time available to comply with the IHM regulations is short.

The Hong Kong Convention requires a certified Inventory of Hazardous Materials (IHM) for each vessel no later than five years after the Convention enters into force, which seems likely to be some years ahead of us. Nevertheless, the EU has implemented the EU Ship Recycling Regulation (EU SRR), setting a clear deadline for IHM onboard. The EU Regulation entered into force in 2013 allowing the industry seven years to comply with the requirement. Legislators have also pro-vided guidelines to support the process like e.g. Guidelines for the Development of IHM (Res. MEPC.269(68)); Guidelines for Safe and Environmentally Sound Ship Recycling (Res.

MEPC.210(63)) and; ECSA Best Practice Guidance on IHM.

The IHM is needed to help ship owners identify of suit-able ship recycler when needed. It can be used to identify risks during ship operations as it informs the crew, repair and conversion yards about hazardous materials onboard, contributing to incident and accident preparedness and re-sponse. It enables ship recyclers (which is the main purpose of the conventions) to plan for the recycling of a ship and its hazardous material, to plan decontamination activities us-ing trained workers, select and use of proper PPE (personal protective equipment) and plan in advance the removal and disposals of HazMats (Hazardous Materials).

IHM for new ships New ships have been required to have an IHM onboard from the 30th December 2015 according to the EU Regulation on Ship Recycling. The shipyard is responsible for compiling the IHM, based on information provided by suppliers via the Suppliers Declaration of Conformity (SDoC) and the Mate-rial Declaration (MD) in which the supplier makes a clear statement about whether or not HazMats are contained. If they are contained, the supplier must specify the place and quantity. The EU has added two more HazMats to the regu-lation, the so called PFOS and HBCDD, and therefore the EU IHM is different from the IMO IHM.

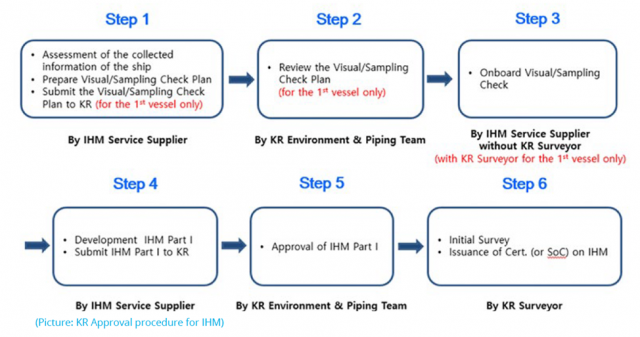

IHM for existing ships The owner is responsible for the IHM which should be pre-pared by the IHM Service Supplier and is based on inves-tigation, samplings, analyses, calculations and documenta-tion. The accuracy of an IHM depends on the expertise at different sampling locations (materials – indicative lists); number of samples taken; detail of documentation; labora-tory standards, expertise and the cooperation between the service supplier and classification society. KR has several ap-proved service suppliers available across Northern Europe.

All existing ships under an EU-flag or any flag when visiting an EU-port are required to have an IHM onboard until 30th December 2020. From the end of 2016, all EU-ships sent for recycling must have a certified IHM onboard as well.

In conclusion, the deadlines are fixed and a huge number of ships need to take action in order to be compliant, as a result, Briese Shipping needs to address this issue this year.

On Board Sampling and Certification Therefore Briese staff should be not surprised when an IHM Service Supplier visits the vessel in near future and when he then starts taking around 100 Samples from the ship.

He will not damage your vessel – relax!

For his report, he need to take samples of the paint, insulation, gaskets and oth-er materials on the vessels.

He will not destroy anything and most service suppliers are willing to repaint any areas that they have taken paint from, afterwards.

After the laboratory results have been analyzed and the fi-nal IHM Report written by the service supplier has been ap-proved by class society, the class surveyor can then come on board to issue the Statements of Compliance (SoC´s) for IHM as per HKC and per EU-SRR (Certification (Statement of Compliance) of Inventory of Hazardous Materials according to Hong Kong Convention (HKC) and European Union Ship Recycling Regulation (EU-SRR)).

The IHM Certificate´s (SoC) will be issued starting from the date of the survey. The certificate interval is five years. The first expiration date of the certificate depends on the flag state and whether the flag state insists on the Harmonized Survey System and whether the flag state has already rati-fied the relevant convention. A renewal survey is to be car-ried out normally at next the Ship Class Renewal.

IHM Maintenance For the next IHM Renewal Survey and any PSC Inspection the IHM System needs to be maintained. If any machin-ery or equipment has been newly installed, removed or replaced or the hull structure including its coating is re-newed, it should be reflected with the entry in the “Records of Change”. Also, it has to be checked that Material Decla-ration (MD) and the Supplier’s Declaration of Conformity (SDOC) for any newly installed or renewed products are attached to the IHM Report.

Ship Recycling In the last three months before the vessel is scrapped, the ship owner will need to check the actual situation on board again and at this stage also, the waste generated in opera-tion (IHM Part II) and any material from stores (IHM Part III) need to be considered for the final IHM report. These days the majority of ships will be recycled in India, Bangladesh, Pakistan or Turkey.