Preparations for IMO 2020 0,5 % sulphur fuel are in progress and it can be mentioned that vessels from the Briese Group are on a good way.

After implementation of the “Ship Implementation Plan” including the “Fuel Management Plan” each vessel has a status quo of fuels on board. Based on this further planning’s in respect of tank cleaning in conjunction with voyage instructions have already been and will be done on a case by case basis.

It is expected that from November 2019 the compliant fuels will be available everywhere; in some locations it is already now. To guarantee a smooth change over Master and Chief Engineer have to stay in close contact with the Operator and Inspection Group in order to have one or two tanks (pending on vessel type) cleaned in time to be able to bunker new fuel.

Cleaning of the tanks is an essential step in this matter and in general it can be mentioned that all tanks, which are cleaned already, regardless of which size of ships had been in a very good condition and remaining deposits in the tanks are minimal.

This already provides a good basis for the upcoming challenges as in future many different types of fuel will be available on the market which will implicit challenges in storage of the 0,5 % S fuel, fuel preparation and handling.

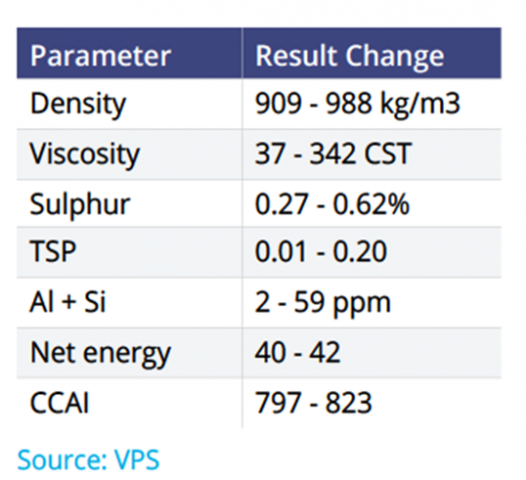

Definition of fuels: Most important parameters of 0,5 % S fuel are density and viscosity. Fuels with high density and low viscosity are most unstable fuels. 0,5 % S fuel can be categorized in three Classes – Class A, Class B and Class AB.

Below gives a rough overview of the main properties of the different Classes.

Class A: More Aromatics Fuels

- A blend with high content of residues from cracking

- High density and low viscosity > High CCAI

- Potentially unstable due to high content of asphaltene

- Existence of Cat fines

Class B: More Paraffinic Fuels

- A blend with high content of long paraffinic chains

- Low density and higher viscosity > Middle CCAI

- Stable fuel

Class AB: Straight Run Fuels (also called hybrid fuels)

- A residue product of the first distillation (Atmospheric)

- The used crude oil has very low Sulphur

- Medium density and medium viscosity

- Quite stable fuel

Presently the first 0,5 % Sulphur fuel are available, and the parameters are varying very much as shown in below table:

Fuel specification – ISO 8217 It is important to keep in mind that the fuel specifications will remain the same. It is still ISO 8217 for Residual marine fuels and Distillate marine fuels. In addition, the products will be specified like RMG 380, RME 180, RMD 80, RMB 30 DMA and DMB.

As described a lot of different type of fuels will come on the market. Consequently, handling of 0,5 % S fuel is very important and following factors must be taken into consideration:

Storage:

- Some fuels (aromatics) might have limited storage qualities

- Heating to be done carefully

- Segregation of Sulphur

Mixing: The Ship Implementation Plan includes in Chapter 7.1: “Bunker strategy / Commingling and segregation” where a couple of bunker scenarios are described. In general, following mixing scenarios of bunker must be taken into consideration:

- VLS HFO 0,5 % S > VLS HFO 0,5 % S= Mixing only allowed after approval of fuel specialists

- VLS MGO 0,5 % S > VLS MGO 0,5 % S= Mixing is allowed

- VLS MDO 0,5% S > VSL MDO 0,5 % S= Mixing is allowed

- VLS HFO 0,5 % S > VLS MGO / MDO 0,5 % S= Mixing is NOT allowed

- VLS MGO / MDO 0,5 % S > VLS HFO 0,5 % S= Mixing is NOT allowed

- Hybrid / Blended fuel > Hybrid / Blended fuel = Mixing NOT allowed; Bunkering only in empty tanks

- 0,50 % sulphur fuel > 0,10 % sulphur fuel: As the 0.1 % sulphur limit in ECASs, which are already established under MARPOL Annex VI, are still in force a mixing of 0,50 % sulphur fuel and 0,10 % sulphur fuel is also not allowed at all!

Treatment:

- Heating in storage tank to be done carefully

- Settling tank temperature to be confirmed from suppliers

- Purifier temperature to be confirmed by suppliers

- Service tank temperature

Change over from 0,5 % S fuel to next 0,5 % S fuel:

- Settling tank must be fully empty

- Service tank as much as possible empty

Currently Briese Schiffahrt is working with charterers on further bunker planning’s and objectives. In addition, charter parties need to be adjusted accordingly and strategic plans to be established that all parties comply with the new regulations and to keep disadvantages for any party as low as possible.

As a result of the implementation of the 0,5 % sulphur fuel it is anticipated that Port State Control (PSC) will increase taking samples of fuel oil from ships. PSC officers may obtain, and test samples taken directly from the fuel oil storage and supply system of a ship; known as ‘inuse’ and ‘onboard’ samples. These samples are separate from the statutory MARPOL delivered sample that is obtained during bunkering and retained on board.

PSC may decide to test ‘inuse’ or ‘onboard’ samples in case of any suspicion of any noncompliance.

1) MARPOL delivered sample The delivered sample is still the sample of fuel oil delivered on board as per Regulation 18.8.1 of MARPOL Annex VI.

2) In-use sample Subject to adoption by MEPC 75 in April 2020 it is expected that from autumn 2021 on vessels must define sampling points that ensure that the fuel collected is the fuel being used by the consumer units on board the ships. Number and location of such sampling points will depend on the ship’s fuel system.

3) On-board sample Also, from autumn 2021 on the IMO has agreed to require ships to have samples of fuel to be carried for use on board. These ‘onboard’ samples of fuel oil not in use by ships shall verify the compliance with the ban of carriage of noncompliant fuel.

It should be noted that IMO made amendments to Appendix VI of MARPOL Annex VI which ensures that a 95 % confidence level for testing of ‘inuse’ samples is applicable. This means that a Sulphur content of up to 0,53 % (0,11) Sulphur must be accepted as compliant. In case sulphur content is higher same will lead to a detention and fuel has to be debunkered.

Anyway fuel oil supplied to ships by bunker suppliers is required NOT to exceed the 0,50 % limit. The sulphur content of fuel oil being bunkered is to be stated on the Bunker Deliver Note (BDN) as per Regulation 18 of MARPOL Annex VI and should be verified by independent laboratory analysis.

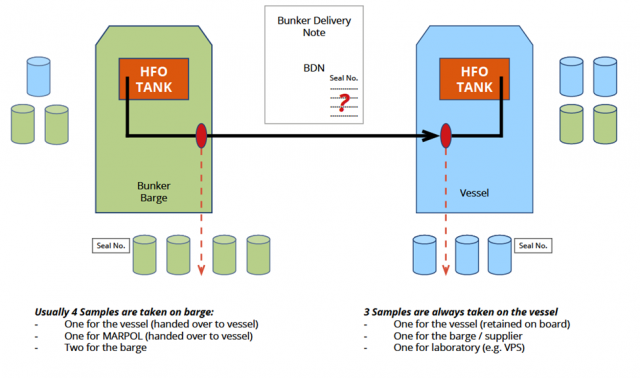

Usually four samples are taken on the barge and three samples are always taken on the vessel.

In case of any dispute on the sample / seal numbers from the Bunker Delivery Note (BDN) are official and therefore it should be always tried to use the vessels sample on the BDN. Anyway, as per MPEC 182(59) the sample location should be on the receiving vessels manifold, but the word “should” implicates that it cannot be requested and there leaves place for interpretation.

In case the supplier does not agree to take official BDN samples on vessel manifold one crew member should always monitor the sampling on the barge and in any case also take samples from vessels manifold. Double seals (from vessel and barge) to be used and all seal numbers to be inserted into the BDN.

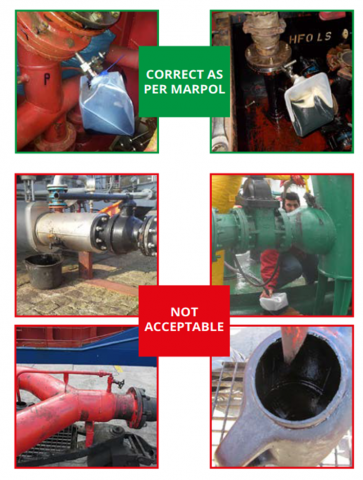

As per MARPOL continuously drip sampling is requested under following parameters:

- Bunker flange with adjustment valve to be installed

- Bunker flange to be installed at the end of bunker line

- Cubic container to be connected and sealed watertight

- Correct adjustment of the adjustment valve and frequent readjustment of same

- Cubic container should be full after bunkering

- Before filling the sample bottles, the cubic container shall be shaken

The left examples show correct and not acceptable arrangements to take bunker samples.

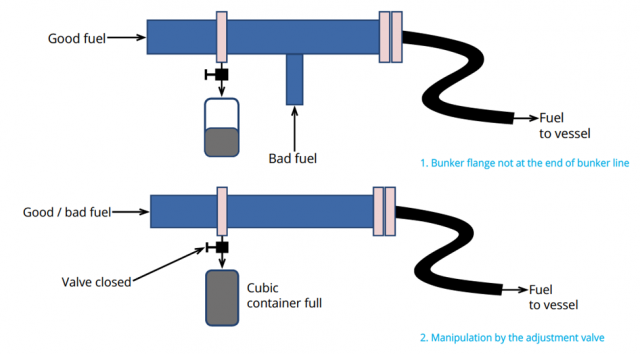

As mentioned, observation of the samples taking at barge manifold is very important as different ways of manipulation of such barge samples have already been observed in the past.

For example if not no drip sampler is being used during bunkering or if the adjustment valve is wrong or wrong positioned.

Below drawings illustrate possible manipulation scenarios.

The next critical point is the sealing of the samples.

Sealing of the samples itself should be observed as well. Also this step bears the risk to be betrayed. One factor may be if the barge has double seals and does not permit to install a second seal from the vessel or the seal is not pulled fully tight and may be used / opened a second time.

Also the delivery / substitution of a full sample before or after bunkering may be taking into account as a possible cheating scenario.

What to do in case of a suspicious activities:

- Contact your operator in case of evidential misbehavior in order to discuss stop of bunkering

- Prepare a letter of protest

- Always samples from vessel manifold to be taken

- Do not sign the BDN with remark or written approval from the operator Finally it can be said that the change to new 0.5% S fuel will be more challenging than RMG380 HFO especially in the way of

- Storage

- Fuel preparation

- Fuel injection adjustment of viscosity.

The potential commercial loss and risk is much higher compared to establishment of the ECA zones. The PSC will focus on the 0.5% S fuel especially in the first stage. In case of no sulphur

compliance fuel is found on board the complete stock must be debunkered.

In addition the much larger quantities and different types of fuel involved enhances the complexity of the ‘Global Sulphur Cap’.

There is no grace period which means from 01.01.2020 the global sulphur limit will be 0,5 % inlet engines. Furthermore, no HFO fuel can be stored on board after 01.03.2020; means any fuel with a sulphur content > 0,5 % should be used or debunkered in advance; rightly before 1st January 2020.