The vessel was drydocked in Northern Europe for 3rd class renewal. Besides the regular class related items and maintenance jobs, some major maintenance and repair jobs were planned for components of the main engine.

One item was the planned maintenance of the crankshaft vibration damper. In order to disassemble and overhaul the vibration damper, the front cover of the vibration damper room has to be removed.

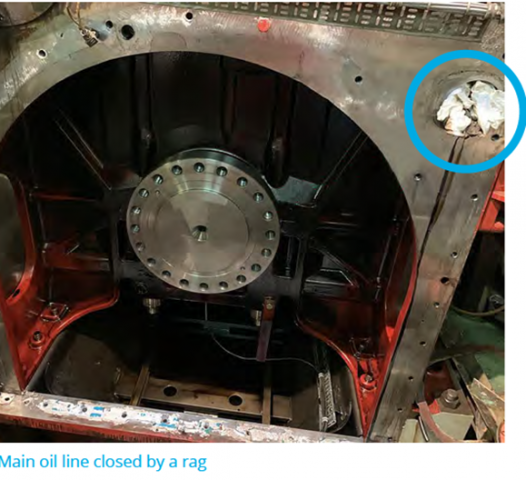

The front cover is closing the main oil line for the main and big-end bearings. After removal of the cover this oil bore was open.

The bearings are vulnerable to any contaminations of the lubrication oil. Already small particles of dust or dirt may cause increased abrasions or damages. Therefore, the pipe must be closed during maintenance by a proper cover.

After overhaul and reinstallation of all parts, the main engine was prepared for a test run at idle speed 420 rpm and increased to 450 rpm.

Shortly thereafter a knocking noise and later smoke has been noticed in the engine room and the engine was stopped.

During the subsequent inspection the big end bear-ing and other components at cylinder station No. 6 revealed big mechanical damages and heat exhaustions.

All indications pointed on an interruption of the lubrication oil supply.

After three days of investigation the lubricating oil line was inspected by endoscope via the holes on the side of engine block and a piece of rag was discovered inside the lubricating oil line. The rag was found in the main supply line from main bearing No. 7. The main bearing No. 7 supplies the big end bearing No. 6. The line was plugged by the rag and conse-quently no oil was supplied to the big end No. 6 and the piston.

A forgotten rag caused a major damage: Main engine cylinder No. 6 big end bearing journal was heavily damaged.

Big end bearing of cylinder No. 6 was completely destroyed.

Big end bearing housing showed severe signs of overheating.

Some friction marks were noticed on the piston and cylinder liner surface.

Finally, a new crankshaft needed to be installed and all oil related parts driven by the engine had to be examined like: 1. Cylinder head’s valve guides, valve rotators 2. Rocker arms / rocker arm brackets 3. Pistons (ring grooves, cooling chambers) 4. Piston pins / small end bushes 5. Cylinder liners 6. Crankshaft journals / bearings 7. Camshaft journals / bearings 8. Camshaft followers (rollers, bearings, pins) 9. Gear train 10. Lube oil pump 11. Cooling water pump 12. Crankshaft vibration damper 13. Turbo charger In summary small mistakes may cause huge damages and costs including spare parts, working hours, surveyors, berth dues and so on.

Consequently, it has to be kept in mind that all openings have to be closed with dedicated materials and / or tools.

Cotton rags are not considered appropriate materials.

In this case an external service company has carried out the job. Anyway, also service companies must be reminded that no cotton rags are to be used in very sensitive areas and the Chief Engineers must double check that all openings are free before assembly starts. Double checks are essential, even if a service company is carrying out the job.