PLT Line Thrower

SOLAS and the LSA Code define which life-saving appl iances (LSA) and are required on board of every vessel, one com-ponent is the line throwing apparatus. It is used to hurl weighted ropes (lines) over long distances and a variety of launching methods are in place.

The line is mainly used for rescue operations on ships and has a number of maritime applications. From transferring supplies, connecting ships, providing supply lines, and most importantly to aiding in rescue operations. Line throwing apparatus are an essential component of any ship’s life-saving equipment.

As pyrotechnic systems are volatile and can be extremely dangerous due to accidental ignition, company decided in 2020 to implement pneumatic based launchers for the whole fleet step by step to comply with the SOLAS requirements.

In normal cases the Pneumatic Line Thrower (PLT) will be delivered with an empty air cylinder. The air cylinder refill is arranged by the Inspection Group and will be done most likely in combination with the regular BA service.

For a minimum of four launches the air cylinder must be filled to a minimum of 207 bar (3000 psi). With 300 bar (4350 psi) the unit can perform a minimum of six launches.

The handling of the PLT should be done according to the instructions manual. During operation hearing protection should be worn.

Before launching following steps have to be done: 1.Screw the launching tube onto the launching unit

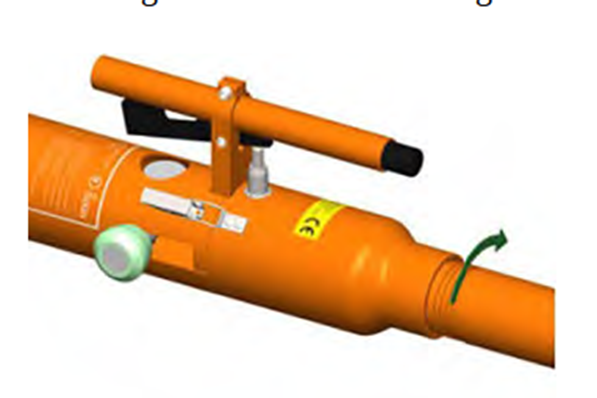

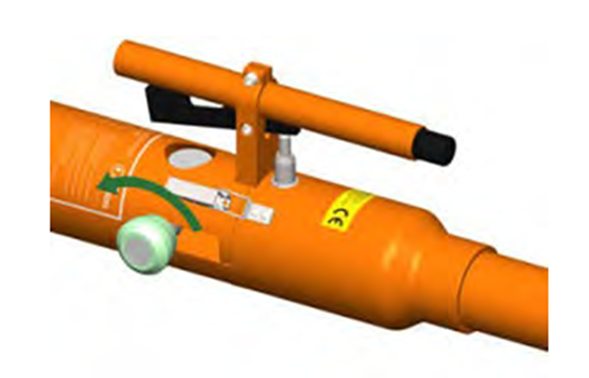

- Open the closing valve for 5–10 seconds until the cham-ber is full. Close the valve immediately without using exces-sive force.

- Pull out the safety line through the center-hole of the end plug of the projectile, approximately 2,5 m.

- Hold the line thrower with the launching tube pointing up-wards. Pull the projectile onto the launching tube with the line in the slot of the end plug. Fasten the end of the line to the line thrower or a secured point.

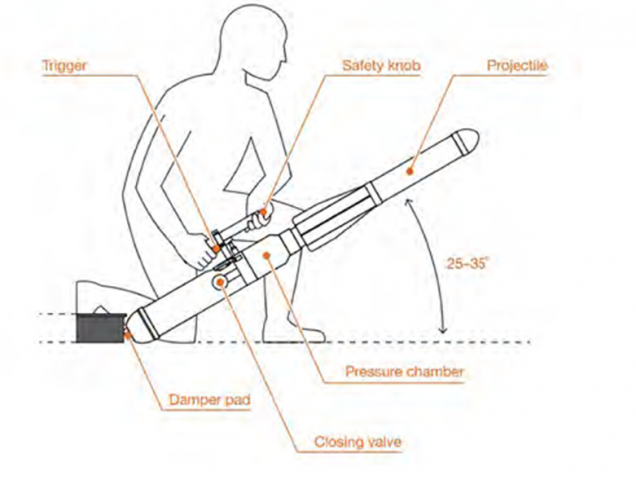

- Due to heavy kickback, it is important that the PLT is well supported during operation. The rear end of the PLT launching unit has a damper pad that must be placed against a solid point that can withstands this force. For maximum distance hold elevation between 25° to 35°. 6. Push and hold the safety knob and aim over the tar-get. Pull the trigger with a firm and rapid movement. The projectile will now be launched.

In general, the PLT air cylinder and closing valve are maintenance free. However, if a leakage is detected, please contact the Inspection Department.

Anyway, it is recommended to check on a regular basis that the pressure of the air cylinder is minimum 207 bar (3000 psi), and maximum 300 bar (4350 psi). According to SOLAS a minimum of four shots are required; with 300 bar up to six shoots are possible. Store the unit at a dry and safe place.

Perform a regular visual inspection to ensure that every-thing stays intact. Make sure that the closing valve is always closed and never leave compressed air in the chamber of the launching unit. If the air pressure drops below that 207 bar, inform the Inspection Department without undue delay in order to arrange a refill accordingly.

It is important to keep the old pyrotechnics on board until the air cylinder is filled. Every delivered PLT contains a USB stick styled like a mini rocket with videos showing the correct handling of the device.